Introduction

As digital technologies increasingly shape every aspect of business operations, packaging has evolved beyond its traditional role as a simple product container. Smart packaging now integrates advanced digital functions that not only protect products but also extend shelf life and enable real-time monitoring of product conditions and safety. Technologies such as sensors, RFID (Radio Frequency Identification), and QR codes allow manufacturers, retailers, and consumers to access accurate information, reduce waste, improve logistics efficiency, and enhance the overall user experience.

Furthermore, smart packaging supports the circular economy by enabling end-to-end lifecycle tracking, reducing reliance on virgin materials, and increasing recycling rates. As a result, it has become a critical component of modern industries that emphasize safety, operational efficiency, and long-term sustainability.

What is smart packaging?

The primary functions of packaging are

(1) to protect and preserve product quality until the product reaches the consumer,

(2) to communicate essential information about the product, and

(3) to provide convenience during transportation, storage, and usage.

In the context of food products, packaging is designed to prevent leakage, breakage, and contamination, while also communicating important details such as manufacturing and expiration dates, nutritional information, and preparation instructions—for example, indicating whether the package is safe for microwave heating. Effective packaging further supports efficient handling and logistics throughout the supply chain.

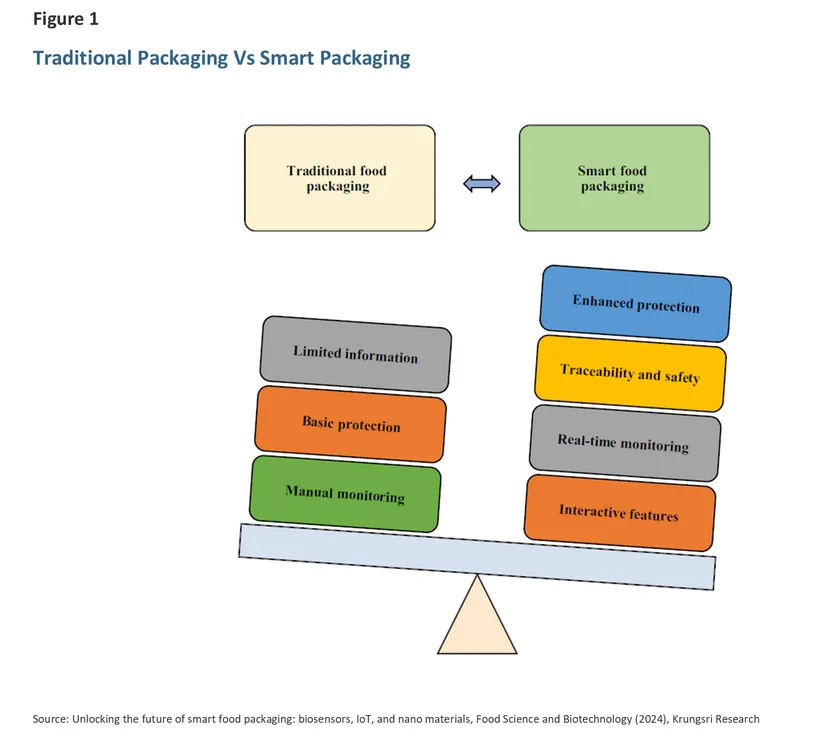

However, traditional packaging is increasingly unable to meet evolving market trends, including more diverse consumer demands, greater emphasis on health and food safety, increasing product complexity, intensified industry competition, and global pressures to support the circular economy and reduce carbon emissions from production processes. These factors are driving packaging manufacturers to innovate and adapt in order to respond to these changes and maintain long-term competitiveness.

In response to shifting market demands, businesses have developed smart packaging, which not only performs the protective functions of traditional packaging but also helps extend product shelf life and facilitates the communication of product information across the supply chain and to end consumers. Smart packaging is generally classified into two categories: active packaging and intelligent packaging.

-

Active packaging is designed to enhance product quality, prolong shelf life, and reduce spoilage through interactions with the product or the internal atmosphere of the package.

-

Within this category, absorbing or scavenging systems work by removing specific substances that could compromise product quality. Examples include moisture absorbers commonly found in snack packaging, oxygen scavengers that minimize oxidation and inhibit microbial growth—such as oxygen-absorbing components in plastic beer bottle caps that extend shelf life by an additional three to six months—and ethylene scavengers used to slow the ripening of fruits and vegetables.

-

Another form of active packaging involves releasing systems, which dispense beneficial substances into the food or surrounding environment to maintain quality. These may include preservatives, antimicrobial agents, antioxidants, flavorings, or enzymes that are incorporated into small sachets or coated onto the packaging material. A widely used example is ethanol emitters in bakery products, which help inhibit mold formation and extend storage life.

-

Intelligent packaging refers to packaging systems that monitor, detect, and communicate the condition of the packaged product or its surrounding environment. By transmitting real-time information about changes or the current status of the product to manufacturers and consumers, intelligent packaging helps maintain food quality, extend shelf life, and enhance overall food safety. These systems often integrate technologies such as sensors, indicators, and tracking devices to continuously assess and communicate relevant data about the food inside the package.

-

A common application involves monitoring product quality and safety through tools such as time–temperature indicators (TTIs), which record the temperature history of a product throughout storage and transportation. TTIs produce a visual response when a product is exposed to unsuitable temperatures, alerting users to potential risks such as microbial growth or diminished quality. For example, meat products that require consistent low temperatures will cause the indicator to change color if stored improperly for a certain period. Such information enables both distributors and consumers to make more informed and reliable decisions about the freshness and safety of food products.

-

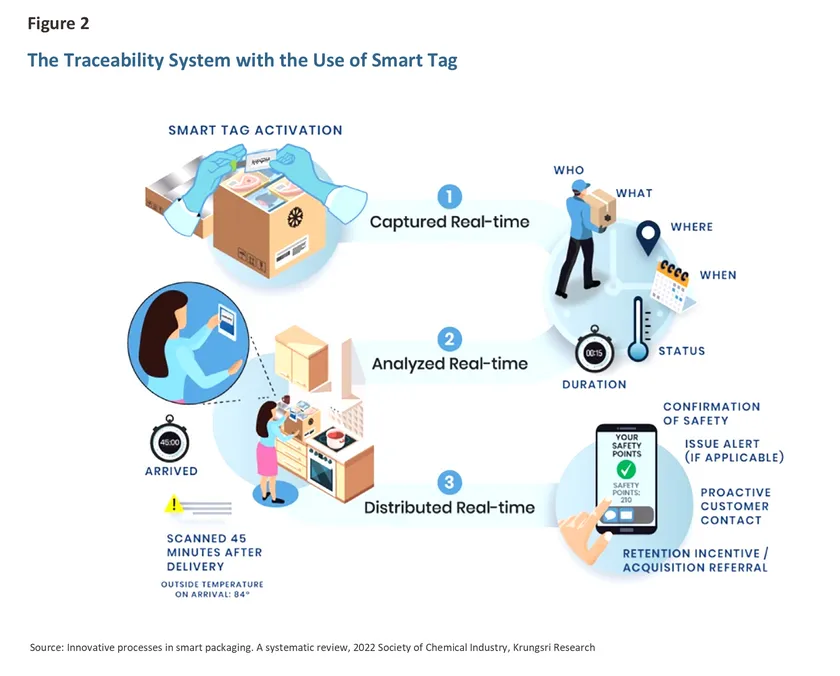

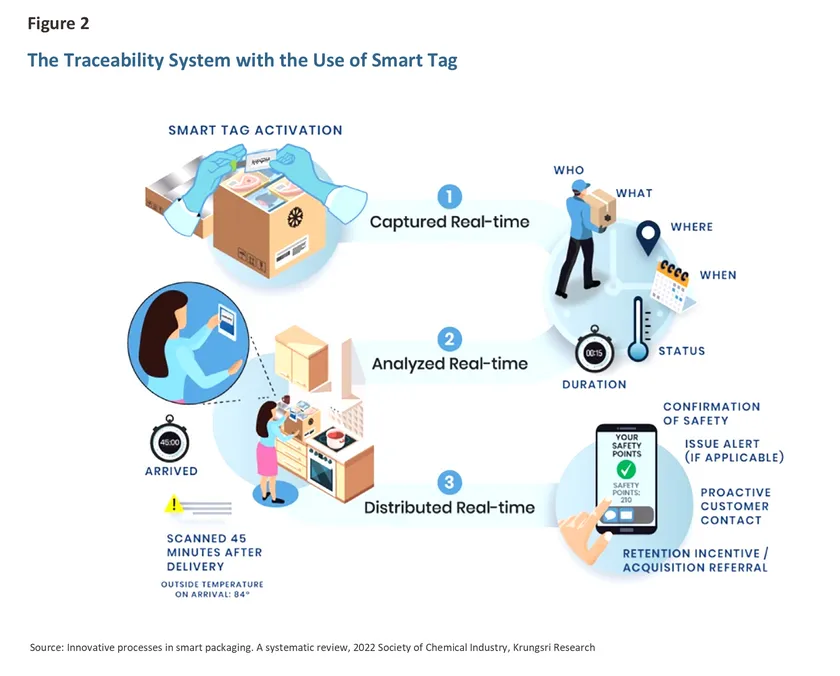

Intelligent packaging also supports tracking and traceability through the use of technologies such as RFID (Radio Frequency Identification) and NFC (Near Field Communication)1/, which are embedded in tags, labels, or chips that store detailed information about the product. These systems can record data related to raw material origins, manufacturing processes, distribution channels, and transportation conditions, allowing manufacturers, distributors, retailers, and consumers to trace the product’s journey throughout the entire supply chain and accurately verify production and expiration dates. Beyond improving transparency, these technologies help mitigate the risk of counterfeiting and enhance food safety by enabling rapid product recalls in the event of contamination or other hazards. As a result, they not only protect consumers but also strengthen brand credibility and reduce legal risks for manufacturers.

-

Intelligent packaging is also used to strengthen customer relationships and enhance the overall user experience by incorporating technologies such as Augmented Reality (AR). AR applications can provide additional information about products, recipes, and nutritional content, display three-dimensional product images, or even allow consumers to virtually try items—such as testing lipstick shades via a smartphone. In parallel, the use of QR codes has become increasingly common, enabling consumers to easily access product details, promotions, and loyalty programs. These features not only elevate the customer experience but also foster long-term brand engagement and effectively increase the perceived value of the product.

The impact of smart packaging on supply chain transformation

The role of smart packaging in enabling new business models

The advent of smart packaging has allowed businesses to develop innovative business models, moving beyond the traditional approach of selling products alone to combining products and services within a Product-Service System. A notable example is SCG Packaging, which operates under a business model known as Smart and Functional Solutions. This approach offers comprehensive services, including design, printing, and production, to deliver smart packaging solutions customized to meet the specific needs of each customer. By integrating products with value-added services, companies can enhance customer satisfaction, differentiate their offerings, and create new revenue streams.

The role of smart packaging in enhancing supply chain efficiency

Smart packaging is increasingly integrated into the Industrial Internet of Things (IIoT), allowing packages to connect and communicate with machines, sensors, and control systems via the Internet. This connectivity enables businesses to collect and analyze real-time data, gaining actionable insights to understand consumer behavior, optimize inventory levels, forecast demand fluctuations, and pinpoint inefficiencies throughout the supply chain.

-

By leveraging data from smart packaging interactions, businesses can gain a competitive advantage through enhanced customer insights. Technologies such as QR codes and NFC allow companies to differentiate products and implement consumer-centric strategies more effectively. Insights from these interactions help identify unmet needs among different customer segments, evaluate willingness-to-pay, and design new packaging solutions that better meet consumer demands, providing a strategic edge over competitors who have not adopted these technologies.

-

Smart packaging also facilitates automated inventory management and replenishment. Retail shelves equipped with RFID-enabled packaging can detect low stock levels and automatically reorder products, while smart waste bins track discarded items to optimize inventory and minimize waste. These automated systems improve operational efficiency and streamline processes across the retail supply chain.

-

Furthermore, in the case of perishable goods, smart packaging is evolving to support predictive maintenance and quality control. Advanced algorithms analyze sensor data to forecast future product quality and estimate remaining shelf life, enabling retailers and consumers to receive alerts when products approach expiration. This predictive capability reduces spoilage, enhances quality control, and ensures a safer and more efficient supply chain.

The role of smart packaging in driving a circular economy

Smart packaging is poised to become a major driver of circular economy initiatives, allowing manufacturers to monitor the full lifecycle of packaging through RFID technology—from production and distribution to disposal and reuse. This capability enables more efficient management of packaging materials, reducing waste and resource consumption.

Additionally, smart packaging can enhance recycling rates and reduce dependency on virgin materials. For instance, containers embedded with smart tracking systems can be effectively traced and collected, supporting the implementation of sustainable closed-loop systems2/. By integrating these technologies, businesses can contribute to a more resource-efficient and environmentally responsible supply chain, aligning operational practices with the principles of a circular economy.

Thailand’s Smart Packaging Industry

In recent years,

Thailand has seen a steady increase in companies entering the smart packaging sector, with major players from the traditional packaging industry driving market development. At the same time, businesses in the food and beverage, pharmaceutical, and personal care industries have been the most proactive in adopting smart packaging technologies to enhance product value and create differentiation.

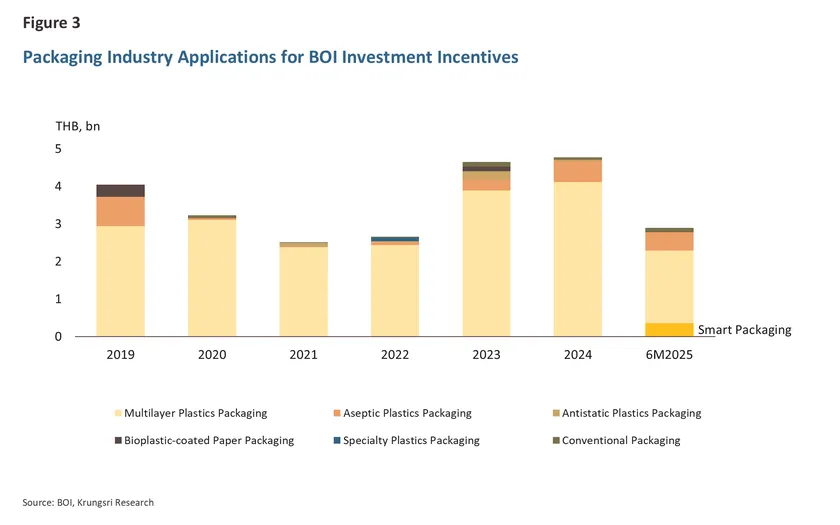

In 2021, the Board of Investment (BOI) upgraded the packaging industry by introducing “smart packaging” as a business category, supporting the principles of the Bio-Circular-Green (BCG) Economy. Despite this,

investment promotion applications submitted between 2019 and 2025 have largely remained concentrated in traditional packaging segments that focus on product protection, such as multilayer plastics, aseptic plastics, and antistatic plastics.

Applications specifically targeting smart packaging only began emerging in the first half of 2025, indicating that Thailand’s smart packaging industry is still in an early, embryonic stage, with considerable potential for growth and future innovation.

Krungsri Research View

Smart packaging relies on advanced digital infrastructure to support the collection, storage, and analysis of data, which remains a limitation within Thailand’s supply chain, comprising manufacturers, retailers, and logistics providers. Many sectors currently lack sufficient capability to handle the complexity of smart packaging systems.

At the same time, a portion of consumers still lack understanding and confidence in the benefits and safety of smart packaging, which constrains market growth.

However, if these challenges can be overcome, the adoption of smart packaging has the

potential to enhance the efficiency of Thailand’s production supply chain, strengthen the competitiveness of manufacturers, retailers, and logistics providers, and serve as a key driver for the food, beverage, and healthcare industries. Additionally, it can contribute to achieving the country’s

circular economy goals.

References

Elsevier (2018) Smart packaging: opportunities and challenges. Retrieved November 14, 2025 from https://www.sciencedirect.com/science/article/pii/S2212827118304104

Food Science and Biotechnology (2024) Unlocking the future of smart food packaging: biosensors, IoT, and nano materials. Retrieved November 25, 2025 from https://link.springer.com/article/10.1007/s10068-023-01486-9

Journal of Food Science (2020) The role of smart packaging system in food supply chain. Retrieved October 20, 2025 from https://ift.onlinelibrary.wiley.com/doi/10.1111/1750-3841.15046

Mckinsey & Company (2019) No ordinary disruption: winning with new models in packaging 2030. Retrieved October 25, 2025 from https://www.mckinsey.com/industries/packaging-and-paper/our-insights/winning-with-new-models-in-packaging

Society of Chemical Industry (2022) Innovative processes in smart packaging. A systematic review. Retrieved November 2, 2025 from https://scijournals.onlinelibrary.wiley.com/doi/10.1002/jsfa.11863

วารสารกรมวิทยาศาสตร์บริการ ‘มาทำความรู้จักกับ active และ intelligent packaging’. Retrieved November 11, 2025 from http://lib3.dss.go.th/fulltext/dss_j/2566_72_223_p.26-29.pdf

วารสารการบรรจุภัณฑ์ (Packaging Thailand) ‘เรื่องเด่น เปิดโลก smart label: จากกจุดเริ่มต้นสู่บทบาทสำคัญในอุตสาหกรรมยุคใหม่’. Retrieved November 13, 2025 https://www.tistr.or.th/Industrials/wp-content/uploads/2025/01/69-2.2.pdf

1/ RFID technology is primarily used in backend operations, enabling manufacturers, distributors, and retailers to track, trace, and manage packaged products throughout the supply chain. In contrast, NFC technology is applied in customer-facing interactions, providing secure, real-time communication between the packaging and the consumer’s smartphone. This distinction allows RFID to enhance operational efficiency while NFC strengthens consumer engagement and product transparency.

2/ A closed-loop system is a recycling process designed to recover used materials and reprocess them into the same product or a product of comparable quality. The core principle of this system is to maintain a closed cycle of material use, preventing long-term waste generation. By implementing such systems, businesses can reduce reliance on virgin resources and minimize environmental impacts throughout the entire product lifecycle—from the collection and reprocessing of used materials to the production of new goods. This approach supports sustainability and aligns with the goals of a circular economy.